- +81-76-275-7558(Weekday 8:30 - 17:30)

- Download of our catalogs

- language

Pressure vessel, boilerBiomass boiler

- Home

- Product information

- Pressure vessel, boiler

- Biomass boiler

- Home

- Find products from its purpose

- Machines for waste and recycling

- Biomass boiler

Main usage

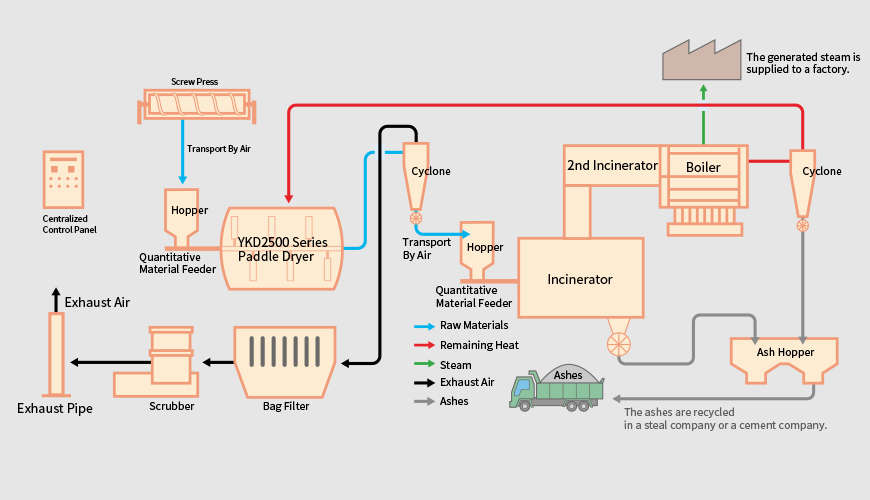

This is a machine to obtain steam or hot water by combusting wastes or solid fuels.

- Object items

- Wood chips, paper sludge, tea residue, plant wastes, the solid fuel by waste plastics. Various wastes such as sludge.

The mechanism of Biomass boiler

It is a tubular type boiler.

There is a number of steam pipes inside the can body, which is filled with water. The water is heated by the combustion gas which is obtained through burning wastes and solid fuels inside the combustion chamber, and generates steam.

Features of Biomass boiler

- Drastic reduction in carbon-dioxide emission is possible.

- Fuel cost can be cut down by using waste materials.

- Drying and combusting wastes can be conducted continuously when arranging a YKD series paddle dryer side by side.

Drying cost can be also reduced by using the discharged gas from the boiler. - By preheating the air for sending the discharged gas from the boiler to a combustion chamber, heat loss is reduced, and the efficiency of boiler will increase.

This also helps to suppress the generation of clinker, because it can improve combustion efficiency.

The size of the machines

* The number below is in the case of a wood chip firing boiler. We need to design individually for other fuels.

| – | TRW-350 | TRW-500 | TRW-750 | TRW-1000 | TRW-1500 | TRW-2000 | TRW-3000 | |

|---|---|---|---|---|---|---|---|---|

| Capacity | Equivalent evaporation(kg/h) | 420 | 600 | 900 | 1,200 | 1,800 | 2,400 | 3,600 |

| Maximum pressure(kg/cm3) | 10 | |||||||

| Electrical heating area(m2) | 9.8 | 14.8 | 24.8 | 29 | 46.5 | 59.5 | 88 | |

| The amount of incinerating wood chips(kg/h) | 75〜95 | 110〜130 | 160〜200 | 220〜270 | 330〜400 | 450〜540 | 670〜800 | |

| the surface area of fire beds(m2) | 0.6 | 0.7 | 0.8 | 1.2 | 1.5 | 1.8 | 1.98 | |

| Stock capacity(m3) | 0.6 | 0.9 | 1.5 | 1.9 | 2.4 | 3.6 | 5.4 | |

| Water supply device | Capacity(l/h) | 500 | 1,250 | 2,400 | 4,100 | |||

| Water supply tank | 500 | 1,000 | 1,500 | 2,000 | 2,500 | 3,000 | 4,000 | |

| Main steam valve(m/m) | 40 | 50 | 65 | 80 | 80 | 100 | 100 | |

| Chimney | Diameter(m/m) | 300 | 300 | 390 | 480 | 480 | 580 | 580 |

| Height(m/m) | 7,320 | 7,320 | 9,800 | 12,200 | 12,200 | 14,600 | 18,260 | |

| Electric capacity(KW) | 6 | 10 | 27 | 30 | 36 | 38 | 42 | |

| The size of boiler room A×B(m) | 5.0×7.5 | 5.5×8.3 | 6.0×10.8 | 6.0×11.5 | 7.5×12.8 | 8.0×14.5 | 9.0×16 | |

| Boiler expert’s license | Class-2 boiler expert’s license | Class-1 boiler expert’s license | ||||||

Frequently asked questions

- Can you propose the detailed running cost?

Yes. If we can have information such as treatment capacity, and treatment time, our sales staff will submit you the detailed running cost.

- Any certification required to operate this machine?

Class-2 boiler expert’s license is required to operate the machine with total heat transferring area smaller than 25m2 . Class-1 boiler expert’s license is necessary for the machine with less than 500 m2 – transferring area.

- What kind of fuels are used for this machine?

The fuels approved for biomass fuels can be used.

We will perform tests at our research laboratory for fuels with no past results.

- How maintenance or exchange of consumables should be done?

It depends on the frequency of the customers’ use, but we recommend a couple of times a year.

We offer lists of consumables when delivering.

We can provide test in advance depending on customer's requests.

We conduct tests to propose our customers the product that suits their expectation best.

Expense for testing varies depending on its contents and terms. We are flexible, so please consult with us.