- +81-76-275-7558(Weekday 8:30 - 17:30)

- Download of our catalogs

- language

DryerVacuum and high frequency dryer

- Home

- Product information

- Dryer

- Vacuum and high frequency dryer

- Home

- Find products from its purpose

- Machines for timbers

- Vacuum and high frequency dryer

Main usage

This can provide high-quality drying in short time period.

- Object items

- Broad leaf trees, woods of conifers, veneers, furniture,

The mechanism of Vacuum and high frequency dryer

Woods are heated by the molecular motion of the moisture inside the woods, which is caused by high frequency waves.

By utilizing the fact that the electrical resistance of wood becomes bigger and the voltage become high, drying automatically finish, when the voltage achieves the setting value.

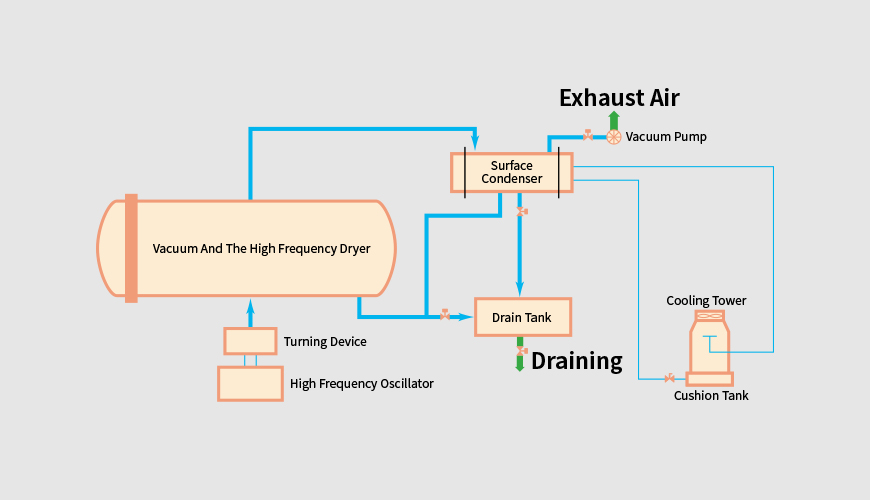

After material are invested to this machine, it is heated by high frequency wave, while reducing the pressure inside by the vacuum pump.

The evaporated moisture is condensed in the surface condenser, and it will be discharged as drained water after being collected in the drain tank.

Features of Vacuum and high frequency dryer

- The water contents of finished products can be very consistent, because they are heated by high frequency wave.

- Drying time can be shorten.

- Since it is dried with low temperature, clack, distortion, or discolorations of material can be suppressed.

- This drying can apply various materials such as veneer sheets, or even large cross-section lumbers.

- Distortion of the materials can be suppressed by using hydraulic presses.

- This can disperse and harden tree tars

- Crosswise piling work will not be necessary.

Frequently asked questions

- How big is the machine?

We are able to propose the best scale and layout option, based on the size and the treatment capacity of materials, and the space to install. Please feel free to ask us.

- Can you propose the detailed running cost?

Yes. If we can have information such as treatment capacity, and operation cycle, our sales staff will submit you the detailed running cost.

- How long it takes to complete drying?

It varies, depending on material, so we strongly recommend to perform test at our laboratory.

- Regarding the maintenance frequency.

We offer lists of spare parts and consumables.

Based on the operational condition of the machine, we will suggest adequate inspection frequency.

We can provide test in advance depending on customer's requests.

We conduct tests to propose our customers the product that suits their expectation best.

Expense for testing varies depending on its contents and terms. We are flexible, so please consult with us.