- +81-76-275-7558(Weekday 8:30 - 17:30)

- Download of our catalogs

- language

Machines for timbers

- Home

- Find products from its purpose

- Machines for timbers

Product line-up for timbers

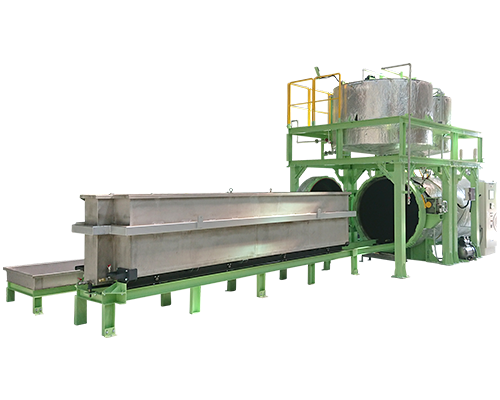

- Vacuum and pressure impregnation machine for wood (Wet)

- This is the machine which can impregnate various kind of chemical solutions into timbers. Depending on the use of woods, it can add values, for example, antiseptic, insecticide or fire retardant.

Injecting amount can be managed by setting the flowmeter, it does not waste chemical solutions. We can provide total suggestions not only optional devices such as a dryer, a cleansing device, or a measuring device for quality management, but also introducing chemical manufactures. - See more detail

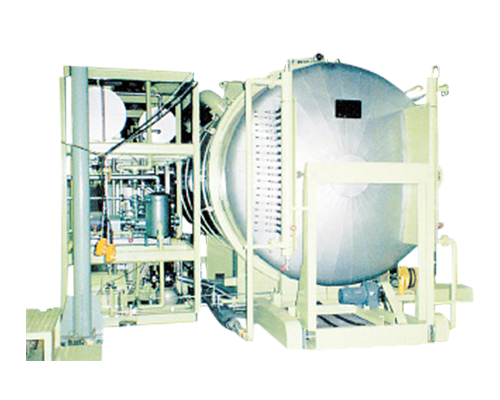

- Vacuum and pressure impregnation machine for wood (Dry)

- This machine can process injection of preservatives or antitermite agent through drying by high frequency wave, in a full-automatic manner.

As there is no dimensional change occurred during the antiseptic process, it is possible to provide antiseptic treatment even to processed products, plywood with adhesives, for examples.

No re-drying after the process is necessary as water is not used, and the solvent used will be collected and reused, being able to achieve reduction in labor and cost. - See more detail

- Vacuum and high frequency dryer

- By using high frequency wave, it can dry materials through the center of woods with low water contents, so that it can produce the products with high added value.

This machine can process various size of woods from veneers to large diameter woods. We will support to find the best processing cycle for each wood material by conducting pretest in our research laboratory or trials at the customer's site. - See more detail

- Vacuum and hot air dryer

- This dryer is particularly fit for hardwood which easily cracks or twists. By drying at low temperature, using hot water as a heat source, it is possible to produce high quality material.

As a heat source, steam and hot water can be used; hot water is used at lower temperature and steam is used at high temperature. Thanks to vacuum conditions, it is possible to dry at low temperature and low humidity level.

It is also possible to add high frequency heating method in option. - See more detail

- Steam blasting machine

- By exhausting steam in a very short time, it is possible to extract components or to destroy the cells of the processed product.

Repeat steaming and blasting type destroys cell walls and makes easy to collect the components of the processed product.

By using only single blasting process, it is possible to crush the processed product. This machine is useful to improve the use of biomass products. - See more detail

- Vacuum and hot board dryer

- This is the machine which dries materials by contacting hot board while the boiling point of water is lowered in the vacuum condition.

Low temperature type can suppress discoloration by drying material with their constituents being kept.

In high temperature type, heat treatment can be processed with the heating medium of 200 deg C or higher.

Materials in every tier can be dried uniformly and drying food is possible by using trays. - See more detail

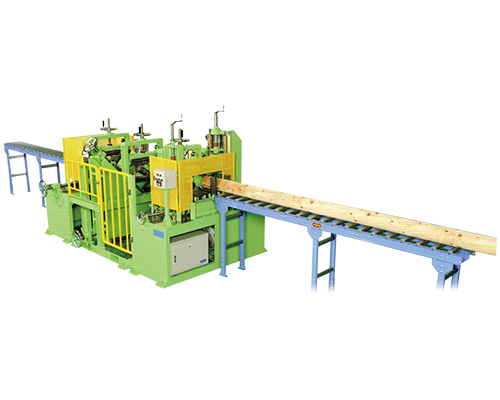

- Incising machine

- This machine makes impregnating difficult-to-impregnate woods possible by processing the surface of woods.

Making holes at the materials surface with the cutting tool that we developed uniquely, this machine enables impregnating chemicals into the materials which had been difficult to be impregnated conventionally. This consequently contributes to the reduction in injecting and drying time, and, uniforming the amount of injecting chemicals.

4-axis method can incise four fazes with one pass. - See more detail