- +81-76-275-7558(Weekday 8:30 - 17:30)

- Download of our catalogs

- language

DryerYVD series, vacuum paddle dryer

- Home

- Product information

- Dryer

- YVD series, vacuum paddle dryer

- Home

- Find products from its purpose

- Machines for food

- YVD series, vacuum paddle dryer

Main usage

This machine can dry materials or waste materials, with relatively low temperature(40℃~)

- Food products

- Keep original flavor of food products by reducing oxidization and heat deterioration.

- Residue, Sludge

- Reduction of cost for industrial waste disposal, a fertilizer, or biomass fuels

- Object items

- Chemicals from chemical industry, Pharmaceutical products, resin, and fine chemicals can be dried.

The mechanism of YVD series, vacuum paddle dryer

The boiling point of water increases when external pressure is high and decreases when it is low.

By heating under vacuum condition inside the drying kiln, the boiling point of water contained in the materials decreases and the material will dry at low temperature as around 40℃.

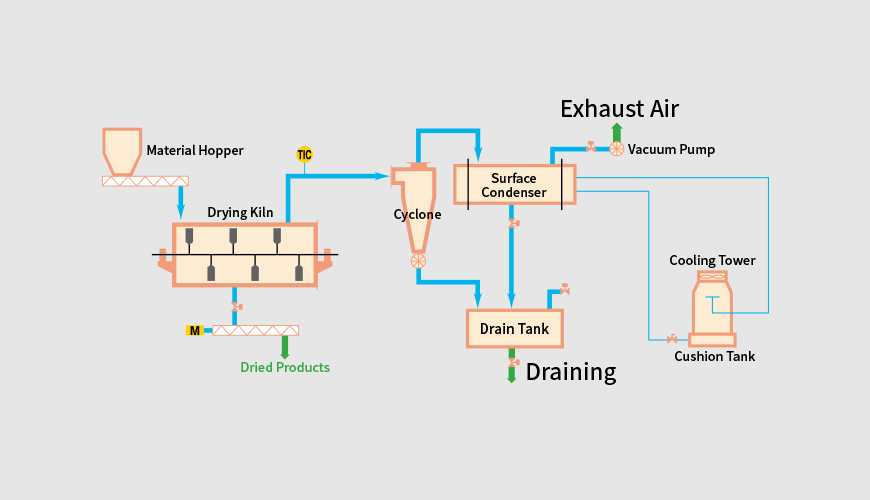

After materials are invested to this machine, the vacuum pump will start to reduce the pressure inside the drying kiln, and this leads to decrease the boiling point of water contained in the materials. At the same time, steam is introduced to the double fold jacket and shafts, which makes paddles to stir materials. The evaporated moisture is condensed in the surface condenser, and it will be discharged as drained water after being collected in the drain tank.

Features of YVD series, vacuum paddle dryer

- Since materials are dried at low temperature under highly vacuumed condition, the original flavor of materials can be maintained, suppressing oxidization and heat deterioration.

- The temperature around this machine is near room temperature, because materials can be dried with low temperature. Inside of the main tank is vacuumed and evaporated moisture is discharged as a drained water, so that this machine emits almost no odor during processing.

- Steam and hot water can be used as a heat source.

- Compered to conventional drying methods this vacuum paddle dryer is excellent in safety, so unmanned operations or night operations is possible.

Frequently asked questions

- How big is the maximum and minimum processing capacity of this machine?

The minimum processing capacity is 30 kg per batch and the maximum is several tons per batch.

For more details, please ask our staff.

- Can you propose the detailed running cost?

Yes. If we can have information such as treatment capacity, the initial temperature of materials, the final temperature of products, processing time, etc., our sales staff will submit you the detailed running cost.

- Can Yasujima make trial dried products in order to see what the finished condition of materials is like?

We have its small size test machine in our research laboratory and recommend that the customers considering to introduce this machine should perform pre-test.

During the trial, the customer can directly check the finished condition of materials, and obtained test data can be used as a base for design and manufacture of the real machine.

- Is this vacuum paddle dryer a pressure vessel? Is any licenses required to operate this machine?

The drying kiln is not a pressure vessel, because it is vacuumed(under Japanese standard).

When taking steam into double jacket, the machine is classified as Class-2 pressure vessel, and a self-inspection once a year is mandatory (in Japan).

No special license is necessary to operate this machine.

We can provide test in advance depending on customer's requests.

We conduct tests to propose our customers the product that suits their expectation best.

Expense for testing varies depending on its contents and terms. We are flexible, so please consult with us.