- +81-76-275-7558(Weekday 8:30 - 17:30)

- Download of our catalogs

- language

Vacuum and pressure impregnation machineIncising machine

- Home

- Product information

- Vacuum and pressure impregnation machine

- Incising machine

- Home

- Find products from its purpose

- Machines for timbers

- Incising machine

Main usage

This makes impregnating difficult-to-impregnate woods possible by processing the surface of woods.

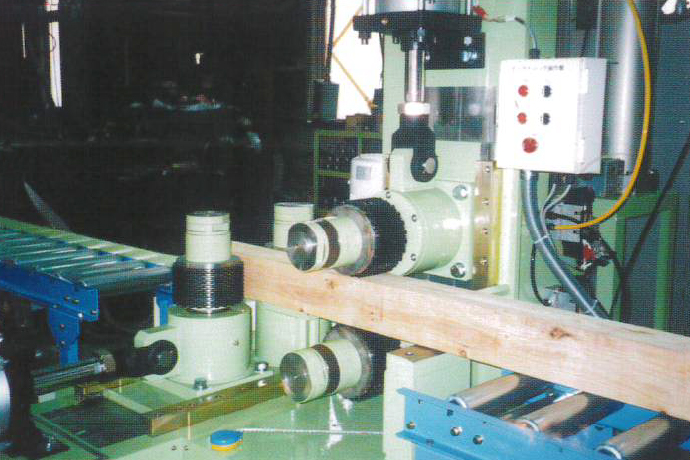

The mechanism of Incising machine

Materials(woods) are set onto the roller conveyer and holes are made at woods surface by the cutting tool, which is developed uniquely by us.

Features of Incising machine

- It is possible to impregnate the materials which were difficult to be impregnated.

- By making holes, impregnating process will speed up and time required can be shortened.

- The variation in injection can be suppressed and even impregnation is possible.

- 4-axis method can incise four fazes with one pass.

- It can not only reduce the cost by speeding up drying speed, but also restrain cracks.

The size of the machine

| KY type incising EX | KY type incising | |||

|---|---|---|---|---|

| KY-4000EX | KY-9000EX | KY-4000 | KY-9000 | |

| The number of axes | 4 axis (bilateral, and vertical arrangement) | |||

| The size of the axis | 190φmm | |||

| Material size can be processed | Width:40-150mm Thichness:40-150mm, Length: 900mm or longer | |||

| Feed speed | 20m/min | |||

| Motors | 3.7kW | 5.5kW | 3.7kW | 5.5kW |

| Machine size | 1200mm×1700mm | 1200mm×1700mm | 1000mm×1500mm | 1000mm×1500mm |

Frequently asked questions

- How often the axis need to be changed?

How fast the axis is worn depends on the material. Please ask us for details, so we can show the past results.

- Can you tell the kind of materials the machine can handle?

In case of the materials we have never handled, we can perform trials at our laboratory. Please feel free to ask us.

We can provide test in advance depending on customer's requests.

We conduct tests to propose our customers the product that suits their expectation best.

Expense for testing varies depending on its contents and terms. We are flexible, so please consult with us.