- +81-76-275-7558(Weekday 8:30 - 17:30)

- Download of our catalogs

- language

Vacuum machineVacuum setter

- Home

- Product information

- Vacuum machine

- Vacuum setter

- Home

- Find products from its purpose

- Other machines

- Vacuum setter

Main usage

Vacuum setter is used for untwisting blended yarns such as nylon, Tetoron, or acetate based fibers, and for setting pleats shapes after pleating.

Features of Vacuum setter

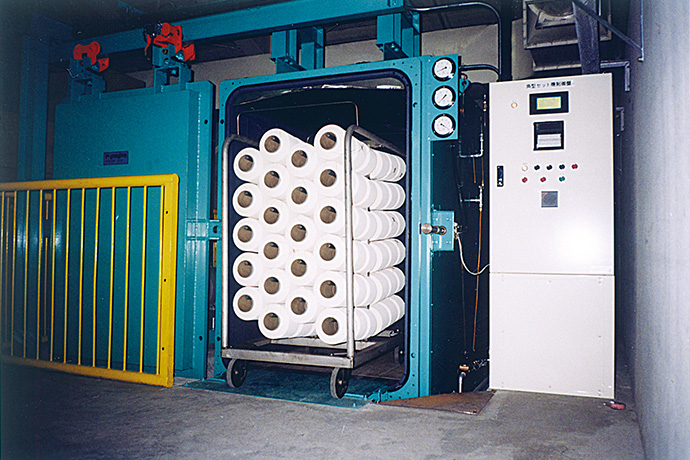

SB-B series, Vacuum setting machine (Square type)

- Safe

As this machine uses only vacuum, there is no risk of explosion. In addition safety devices are equipped, so you can use without worry. - Simple operation

Only you have to do is turning on the switch. Its operation is automatically controlled by electronic control circuit. - No license or inspection is required (inside Japan).

No registration, initial inspection or license is necessary in Japan. - Large loading space

Compared to round type setting machine, loading space of square type setting machine is larger.

SB series, Vacuum setting machine (Round type)

- Full automation type

All operation except loading and unloading of products is fully automated, and products are heat treated under the exact same condition in exact same time period, every time. Thanks to this, products are uniform with little setting unevenness. - Vacuum and heating repeat method

It is highly vacuumed. By repeating vacuum and heating process, steam infiltration to the thread can be progressed rapidly, giving a better heat and humidity repartition. - A wide control temperature range

The temperature can be set from 70℃ to 150℃. and controlled automatically. It is also recorded, and through quality management is possible. - Good drainage structure

As drained water generated inside the setting machine is discharged to a drain tank, vacuuming time can be short and the quality of set thread is improved. - Safety device

The limit switch equipped with the door part stops the operation from starting in case the door is not completely closed. - Automatic stopping device in case of temperature and/or vacuum failures.

In case of failure such as overheating or insufficient vacuuming, the machine will stop automatically. In addition, as the light will indicate the part failure occurred, the cause of failure can be easily figured out…substandard.

Manual stopping device is equipped as standard specification. - Excellent door fastening mechanism

Safe and easy fastening has been realized due to the fastening method using a clutch ring. Since Neoprene rubber packing is used for packing, it has an excellent airtightness and a durability.

We can provide test in advance depending on customer's requests.

We conduct tests to propose our customers the product that suits their expectation best.

Expense for testing varies depending on its contents and terms. We are flexible, so please consult with us.