- +81-76-275-7558(Weekday 8:30 - 17:30)

- Download of our catalogs

- language

Vacuum machineVacuum cooler

- Home

- Product information

- Vacuum machine

- Vacuum cooler

- Home

- Find products from its purpose

- Machines for food

- Vacuum cooler

Main usage

Preserving freshness of foods by using vacuum

- Leaf vegetables, various vegetables

- Keeping freshness of foods

- Processed foods(e.g. boiled rice, other side dishes, etc.)

- Inhibit the propagation of bacteria

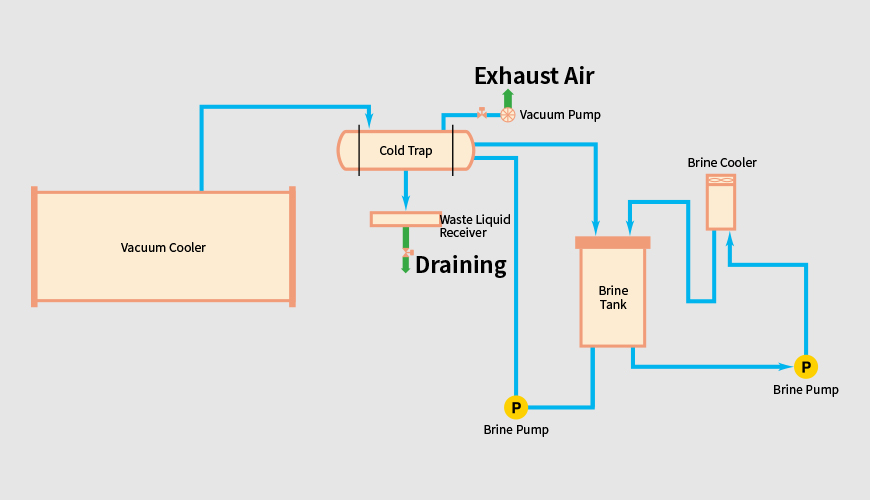

The mechanism of Vacuum cooler

The evaporation temperature decreases when the pressure of the air is lowered. This machine uses this properties to evaporate the water on the surface of foods and cool them.

After materials are set inside the machine, vacuuming pump will be started to decrease the pressure of the chamber and the materials are cooled consequently.

The evaporated moisture will be captured inside a cold trap and be discharged from liquid receiving container, in a liquid state.

Features of Vacuum cooler

- By vacuum cooling fresh vegetables, its respiratory heat can be suppressed and the freshness of foods during transportation can be maintained.

- Thanks to a reduced cooling time, it helps limiting the proliferation of germs.

- It also reduces the load on your freezer during transportation or storage.

Frequently asked questions

- How big is the size of the machine?

We are able to propose the best layout option, based on the treatment capacity, and the space to install. Please feel free to ask us.

- Can you propose the detailed running cost?

Yes. If we can have information such as the kind of materials, treatment capacity, initial temperature of the materials, and treatment time, our sales staff will submit you the detailed running cost.

- Any special training required to operate this machine?

No special training or certification is required because operation of the cooling process is all automated, though we provide initial instruction when carrying out test-runs.

- Where is Yasujima' s main delivery destination?

Machines for vegetables: agricultural cooperative associations and flower markets throughout Japan

Machines for processed foods: food plants handling preserved foods or ingredients for Bento(lunch boxes)

- Regarding the maintenance frequency

Machines for vegetables: Preferably twice a year (before and after the harvest season).

Machines for processed foods: Recommend to perform once a year.

We can provide test in advance depending on customer's requests.

We conduct tests to propose our customers the product that suits their expectation best.

Expense for testing varies depending on its contents and terms. We are flexible, so please consult with us.