- +81-76-275-7558(Weekday 8:30 - 17:30)

- Download of our catalogs

- language

DryerYKD series, high speed paddle dryer for food

- Home

- Product information

- Dryer

- YKD series, high speed paddle dryer for food

- Home

- Find products from its purpose

- Machines for food

- YKD series, high speed paddle dryer for food

Main usage

Drying high-water contents wastes, for example Okara(waste Tohu), various type of residues, and sludge, be able to reduce waste disposal cost, or can even change to new products.

- Raw Okara(bean curd leftovers)

- Dried Okara for food.

- Vegetables such as carrots, radishes, or sprouts.

- Dried vegetables.

- Other foods

- Other dried food products, or dried food ingredients.

The mechanism of YKD series, high speed paddle dryer for food

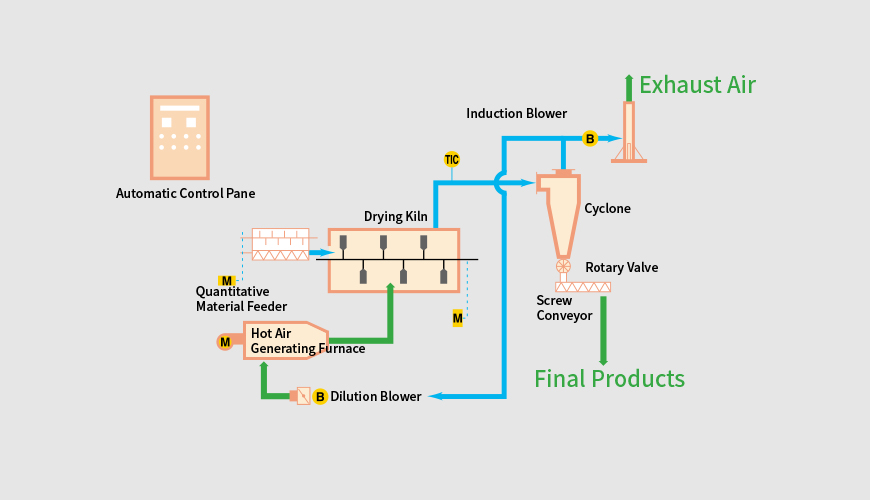

At the same time that materials are injected into the drying kiln from the supply device, 300~450℃ of hot air blows from a hot air generating furnace. This hot air, together with stirring by high speed rotating paddles, the moisture contents of material can be decreased from 80% to 8%.

Dried materials are to be separated through a cyclone and a rotary valve, and sent to next process.

A part of the exhausted air will be returned to the hot air generating furnace, and reused as a heated steam by heating. By using this heat recollection system, its running cost can be reduced by 10-20 %.

Features of YKD series, high speed paddle dryer for food

- In order to prevent degradation of materials and proliferation of germs by transferring and temperature change, Yasujima can design and attach the transferring device exclusively for food according to each customer’s production site.

- The collaborative work by hot air flowing inside the drying kiln and the paddles rotating at high speed makes “first-in, first-out” of materials possible and reduces the risk of heat deterioration and oxidization, by quickly passing through the dryer.

- Our dryer is designed to have the structure, which allows easy cleaning, and the cleaning system we had developed uniquely enabled to reduce a burden of routine cleaning work.

- YKD high speed paddle dryer can offer support from original materials to final products, as being fully equipped with auxiliary equipment, such as transportation, storage, re-processing and packing devices.

- We, Yasujima have full line-up of dryers, so that we can support various production quantities of customers.

Line-ups of Yasujima’ s dryers.

| Model | L(mm) | W(mm) | H(mm) | Processing capacity |

|---|---|---|---|---|

| YKD-100 | 4000 | 2000 | 3000 | 100kg/h |

| YKD-200 | 5000 | 2500 | 3500 | 200kg/h |

| YKD-350 | 7500 | 4000 | 4000 | 350kg/h |

| YKD-500 | 8500 | 5000 | 5000 | 500kg/h |

| YKD-750 | 9000 | 5500 | 5800 | 750kg/h |

| YKD-1000 | 9500 | 6000 | 6000 | 1000kg/h |

| YKD-1500 | 10000 | 6500 | 8000 | 1500kg/h |

| YKD-1740 | 11000 | 7000 | 8000 | 1750kg/h |

| YKD-2000 | 12000 | 7000 | 8000 | 2000kg/h |

The processing capacity above is calculated based on Okara(bean-curd leftovers).

Yasujima can design the alignment of dryers and make suggestions, based on the state of customer’s site.

Please feel free to ask our sales staff if you are interested to install this machine.

Frequently asked questions

- How many types of fuels can be used for this dryer?

We recommend LNG and LPG for use.

If you like to use other fuels like kerosene, fuel oil A, or vegetable waste oil, our sales staff will make suggestions regarding how to deal with them.

- Can you propose the detailed running cost?

Yes. If we can have information such as treatment capacity, the initial water contents of materials, the target water contents of products, initial material temperature, and fuel cost, etc., our sales staff will submit you the detailed running cost.

- Can Yasujima make trial dried products in order to see what the finished condition of materials is like?

We have its small size test machine in our research laboratory and recommend that the customers considering to introduce this machine should perform pre-test.

During the trial, the customer can directly check the finished condition of materials, and obtained test data can be used as a base for design and manufacture of the real machine.

- How maintenance or exchange of parts should be done?

We recommend performing maintenance once a year. Other than consumables like a bearing, or an oil seal, there are no parts the customer need to purchase periodically.

We can provide test in advance depending on customer's requests.

We conduct tests to propose our customers the product that suits their expectation best.

Expense for testing varies depending on its contents and terms. We are flexible, so please consult with us.