- +81-76-275-7558(Weekday 8:30 - 17:30)

- Download of our catalogs

- language

Vacuum and pressure impregnation machineVacuum and pressure impregnation machine for wood (Wet)

- Home

- Product information

- Vacuum and pressure impregnation machine

- Vacuum and pressure impregnation machine for wood (Wet)

- Home

- Find products from its purpose

- Machines for timbers

- Vacuum and pressure impregnation machine for wood (Wet)

Main usage

Injecting various kind of chemical solutions can put high added value on woods.

- Antiseptic and antitermite treatment

- Construction material (Base),Outdoor material (fences, panels,…) Sound reducing panels (for high speed ways…),Wood piles,Outdoor playground equipment

- Finished products

- Construction material (Inner material), Flooring, Car equipment

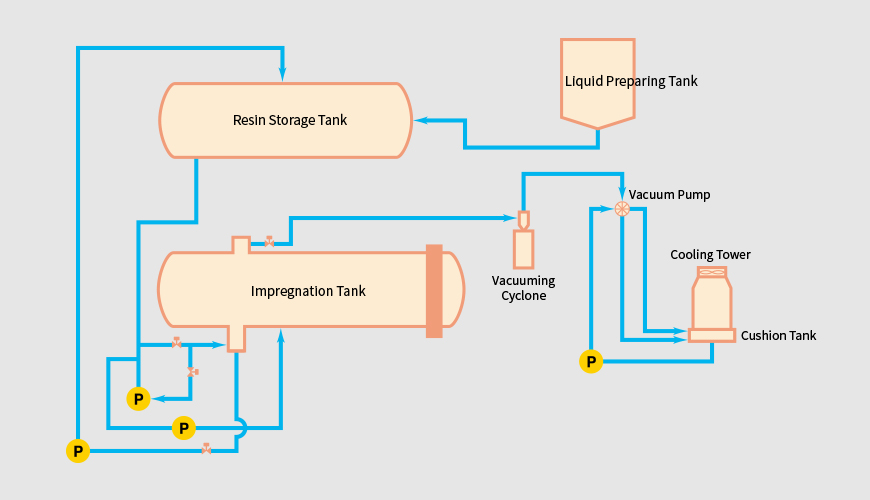

The mechanism of Vacuum and pressure impregnation machine for wood (Wet)

After materials(woods) are set, the air insides the woods will be extracted by reducing pressure.

Chemical solution will be injected with pressure into the vacant space that was created by the extraction.

There are two way of pressurizing. One is liquid pressurizing, which is way to pressurize with liquid chemical by using pumps with the impregnation tank filled with the chemical solution. Another is air pressurizing, that is way to apply pressure by using air compressors.

In case of liquid pressurizing type

Materials are set onto the wheeled platform in a tank and then decompressed. With this decompressed state, the chemical liquid are filled to the tank. When the tank is filled with the solution, pressurizing stars by using a pump.

Pressurizing cycle can be managed by either setting time or setting injection amount with a flow meter.

In case of air pressurizing type

Both materials and chemical solutions are set in a square tray, and the tray is put into the impregnation tank.

After reducing a pressure first, then pressure will be applied by compressed air.

The operation cycle is managed by time setting.

Features of Vacuum and pressure impregnation machine for wood (Wet)

- Because injection amount can be controlled by setting a flow meter, it is possible to prevent excessive injection and save chemical agents(This is liquid pressurizing type only.).

- It is also possible to add functions as heating of solutions or a cleansing system of pipes, based on the customer’s need and the property of chemical solutions.

Frequently asked questions

- How big is the size of the machine?

We are able to propose the best layout option, based on the treatment capacity, and the space to install. Please feel free to ask us.

- Can you propose the detailed running cost?

Yes. If we can have information such as treatment capacity, and necessary additional equipment such as boiler, etc., our sales staff will submit you the detailed running cost.

- Is there other machineries required besides impregnation machine?

We can make comprehensive proposal including the machineries which might be necessary before and after the process(e.g. incising machine, drier, cleaning machine, quality management device, etc.)

Please feel free to consult us.

- Regarding the maintenance frequency.

We will perform periodic maintenance based on the customer’s request.

We can provide test in advance depending on customer's requests.

We conduct tests to propose our customers the product that suits their expectation best.

Expense for testing varies depending on its contents and terms. We are flexible, so please consult with us.