- +81-76-275-7558(Weekday 8:30 - 17:30)

- Download of our catalogs

- language

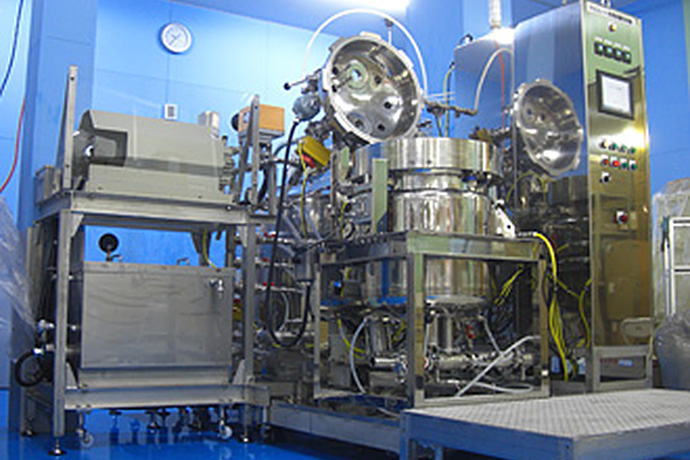

Vacuum and pressure impregnation machineImpregnation machine for food

- Home

- Product information

- Vacuum and pressure impregnation machine

- Impregnation machine for food

- Home

- Find products from its purpose

- Machines for food

- Impregnation machine for food

Main usage

By controlling vacuum, pressure and heating, it is possible to inject liquid or other oily liquid, which not permeating easily, to food products in short time.

- Enzymes, Seasonings

- Various impregnated food products

- Chocolates, Cheeses

- Snacks, Sweets, Dried fruits, Impregnated vegetables

The mechanism of Impregnation machine for food

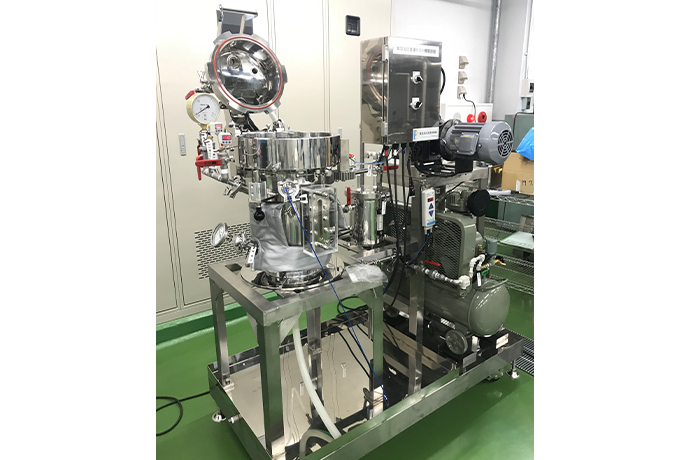

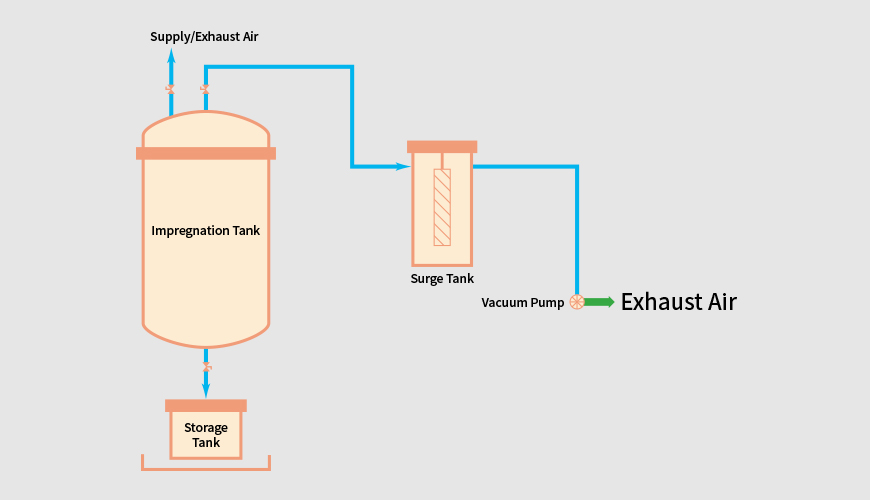

The specialized basket containing materials is set before operating.

After starting, the pressure inside the impregnation tank will be reduced to the setting point, then the impregnating solution will be injected while the basket is rotating.

Depending on materials and solutions, pressure will be added during impregnating process.

After impregnation process completes, solution will return to stored tank, and baskets is rotated at a high speed to separate excess liquid.

Features of Impregnation machine for food

- By injecting enzymes or other additive products, it is possible to create new possibilities and increase the value of your products, not only for vegetables and fruits but also for cookies and dessert.

- Impregnating solution can permeate to inside of the material, compared to the products being just coated, and it can greatly improve tastes and texture by merging the solution and materials.

- Since the solution can be injected to products quickly, it can also improve productivity.

We can provide test in advance depending on customer's requests.

We conduct tests to propose our customers the product that suits their expectation best.

Expense for testing varies depending on its contents and terms. We are flexible, so please consult with us.