- +81-76-275-7558(Weekday 8:30 - 17:30)

- Download of our catalogs

- language

Machines for food

- Home

- Find products from its purpose

- Machines for food

Product line-up for Food

- YKD series, high speed paddle dryer for food

- After raw materials are injected to the machine, as curbing propagation of microorganism, they will be dried in a few minutes at longest. This can be achieved by hot air flowing inside the drying kiln and the paddles rotating at high speed which increases the surface of the drying material by crushing it.

Moreover, we have realized the lowest running cost in this industry by recycling the part of discharged hot air.

It is also possible to add auto ability adjustment, and/or auto cleaning system, which can reduce burdens of food manufacture doing daily production maintenance. - See more detail

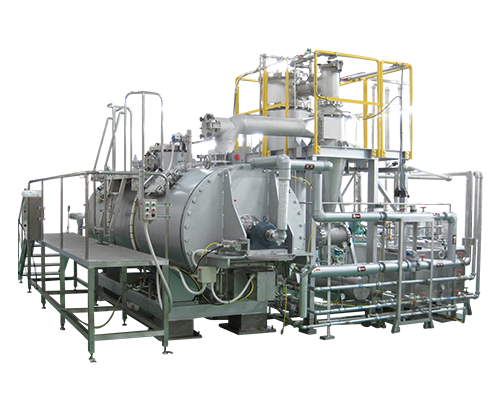

- YVD series, vacuum paddle dryer

- We realized drying materials in low temperature with lowered boiling point of the material with vacuum conditions inside the drying kiln. This machine can also suppress heat deterioration of the material and dry it without impairing its original flavor.

The steam discharged while drying process is collected in a condenser and is discharged as drained water.

If you have trouble of dryers, as high heat temperature or odor issue, this machine is best choice. - See more detail

- Vacuum cooler

- By using vacuum properties, it is possible to cool vegetables or food products within a short time. Thanks to a reduced cooling time, it helps limiting the proliferation of germs and reducing the load on your freezer.

- See more detail

- Freeze dryer

- The boiling point of water in the drying kiln is lowered to below the frozen temperature while being vacuumed, and this leads the sublimation of moistures inside materials and dries the objects.

- See more detail

- Impregnation machine for food

- This vacuum and pressure impregnation machine can inject seasonings or chocolates to various foods and create new flavor or texture.

We have many successful experiences of injecting chocolates and cheeses to snacks and dried fruits by now. - See more detail

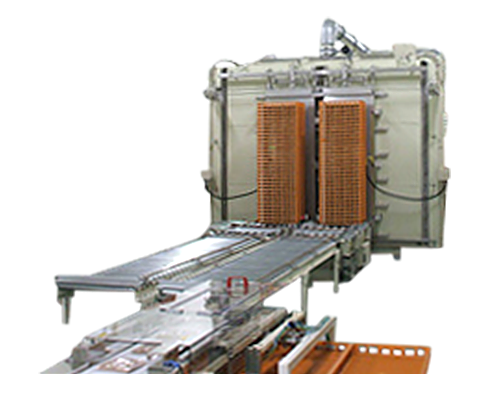

- Continuous sterilization machine

- This machine allows to sterilize and cool materials which have relatively low temperature and doesn't need pressurizing for sterilization.

Materials, as being transported by a conveyer, are sterilized and cooled continuously. - See more detail

- Retort pouch sterilization machine

- This is the machine used to conduct pressure sterilization by steam and cooling. This can be applied to canned foods, which need cooling and being pressurized after pressure sterilization.

- See more detail

- Vacuum concentration machine

- By using vacuum properties, water evaporates at low temperature so it is possible to concentrate the components of the heated solution.

As it is possible to control automatically the volume of solution supplied inside the main tank, this machine has a compact design. By setting a mixer inside the tank, it is possible to refrain the boiling of the solution. - See more detail

- Double fold jacket pressure vessel

- There are two types of double fold jacket pressure vessel. One is no-pressure type, which is suitable for food products(e.g. Tukuda-ni, boiled dishes, or Curry, etc.) and the other is internal pressure type, which fits pharmaceutical products and food also.

As our cookers are made with stainless steel, they are very clean and hygienic.

Compared to burner type cooker, uniform steam supply allows a faster heating without burning.

Handling is easy thanks to the handle for rotating the cooker (option). - See more detail