- +81-76-275-7558(Weekday 8:30 - 17:30)

- Download of our catalogs

- language

Industrial equipment

- Home

- Find products from its purpose

- Industrial equipment

Product line-up for industrial equipment

- Sealing treatment machine

- This is a machine to inject resin such as varnish into motors.

Vacuumed vanish liquid is pressured with air or asphyxiating gas and heated by jackets or internal coils.

Yasujima can design the machine according to the necessary impregnation schedule of customers. - See more detail

- Vacuum oil filling machine for transformers

- This machine can offer vacuum oil filling of insulating oils to transformers.

We can design the machine according to customer's production capacity. - See more detail

- Vacuum drying machine for transformers

- This machine can remove the moisture contained in the transformer before injecting oils to transformers.

According to customers requests, we can offer total solutions by combining with vacuum oil filling machine.

A steam coil or an electric heater can be selected as a heat source. - See more detail

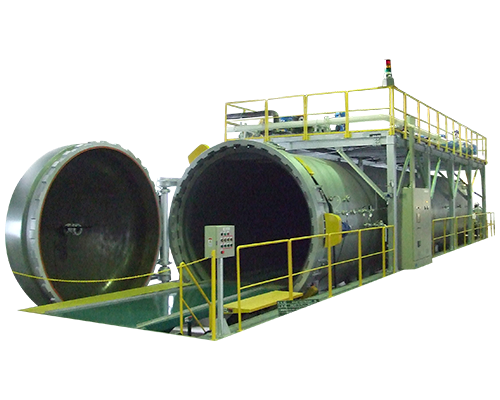

- Autoclave

- Various purposes including molding of composite materials(e.g. plastic reinforced with carbide fibers) or sterilization can achieved by making internal pressure of the vessel high.

Under high pressure, many chemical reactions progress faster, or even the chemical reactions that we hardly see under normal pressure occurs. By using this property, this machine is used for special chemical reactions, molding of physical composite materials, or sterilization in medical and/or biochemical fields. - See more detail

- Impregnation machine for food

- This is the machine to inject resin into small holes of casting products(e.g. aluminum). We can also offer after-vacuum impregnation facilities such as a dewatering tank, a cleaning tank, a drying device.

- See more detail

- Hydrolysis machine

- This is a machine to hydrolyze materials by high-pressure steam.

As processing unutilized resources(wastes) without generating carbon dioxide or dioxin, wastes can become profitable resources without any bad influence on environments.

From wood materials or waste materials an ethanol can be produced, and fuels or composts can be made from other wastes. This machine can remove mercury, heavy metal, chlorine, or cesium. - See more detail

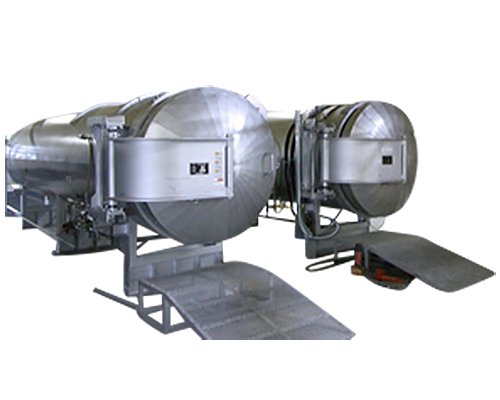

- Vulcanizer

- This machine is used to vulcanize rubber products such as tire. Efficient vulcanization is possible by using a steam heater.

- See more detail